Vieworks brings new era for medical X-ray imaging

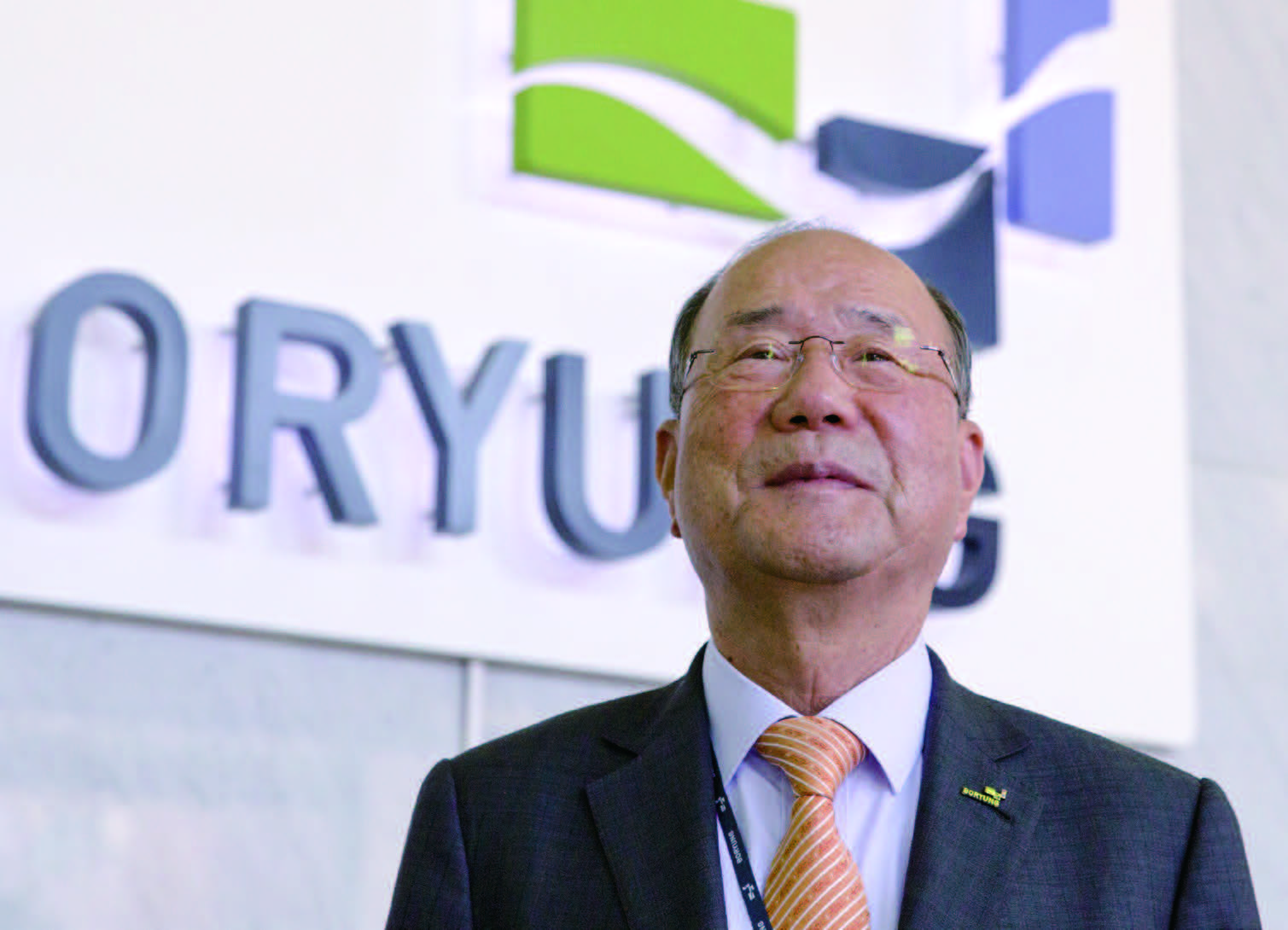

Kim Hooshik

CEO of Vieworks

Kim Hooshik, former engineer for Samsung Aerospace Industries (Samsung Techwin), is the CEO of Vieworks, which designs, develops and manufactures equipment from advanced X-ray detectors to digital imaging systems for digital radiography, digital fluoroscopy and angiography.

Digital radiography (DR) is changing the way medical X-rays are generated. Over the past few years, doctors have come to rely less on conventional X-ray machines and flat panel detectors, the latest class of X-ray DR, are quickly taking their place. Vieworks is one of the major players leading the transition worldwide. “Within five years, DR systems are expected to replace analogue and computer radiography (CR) systems at most major medical institutions in Korea and throughout the developed world,” said Vieworks CEO and President Kim Hooshik in an interview. Vieworks is the world’s third largest manufacturer of flat panel detectors, with a market share of 15 percent. After developing its first product in 2011, the firm has rapidly risen to become a formidable challenger to Trixell and Varian, the two leaders in the global flat panel detector market. “The size of the market is expected to triple in a few years. And we will continue to increase our share of it. This is just the beginning for us,” Kim said. Flat panel detectors can capture X-ray type images and convert them into electronic data that a computer can display in high-resolution. Moreover, they allow users to store and maneuver images easily. Better yet, it only takes about five seconds to obtain an image and patients spend less time exposed to harmful radiation. To sharpen its competitiveness, Vieworks developed Automatic Exposure Detection, which can detect what X-rays can detect without the need of cable connections between an X-ray detector and X-ray generator, Kim noted. “I think the technology was one of the key factors that helped Vieworks grow quickly into the third biggest player in the 400-billion-won ($370 million) global market within a short period of time,” he said. DR rings is hastening the end for the era of traditional X-ray technologies, which have improved little since German physician Wilhelm Rontgen found in 1895 that X-rays would pass through the tissue of humans leaving the bones and metals visible.

In analogue X-ray imaging, different materials absorb the radiation by different degrees. Hard tissues such as bones absorb X-rays, and appear white on an X-radiograph. But the process, in which light-sensitive photographic film overlapped with fluorescent screen is exposed to X-rays and then developed, takes about 15 minutes or longer. Besides, the pictures can neither be manipulated nor shared instantly with others in different locations. Then, the CR system came out. But the technology has lost competitiveness against the cheaper and more durable DR system. “Perhaps the biggest disadvantage of the CR system is the amount of harmful radiation the patient is exposed to, which is twice as much as DR,” Kim said. Today more than 70 percent of Vieworks’ revenue come from its exports to 10 countries, including Germany, Japan and the United States, he said. “The next goal is to increase our share in the market of flat panel detectors for fluoroscopy,” he said. “We have already come up with a prototype for the product and we will start selling this soon.” “If everything goes well, Vieworks will become the world’s third firm to enter the market, which is, for now, dominated only by Trixell and Varian.” Fluoroscopy is an imaging technique that uses X-rays to obtain real-time moving images of the interior of a patient. “The technology, which allows users to see real-time actions such as the heart pumping, can be useful especially for cardiac and upper gastro-intestinal treatment,” Kim said.

Developing ‘glycosuria foot detector’

What makes diabetes one of the leading causes of death in most developed countries is that it can damage a person’s body for years without showing any clear signs. Late detection of the disease raises the risk of serious complications such as amputation of the feet. In cooperation with researchers, led by KAIST Professor Choi Chul-hee, Vieworks has been working to develop a device capable of detecting glycosuria in feet by the speed of blood circulation, Kim said. “Through big data analytics, we can tell whether a person has the problem, but not with absolute accuracy yet,” he said. The device is capable of showing the speed of blood circulation in feet. This is meaningful progress from the existing technology that is only able to tell whether blood vessels are blocked. “If the research goes well, the device may be able to prevent many people around the world from having their feet amputated,” he said. “It could be a medical breakthrough.” However, the research into the technology has recently been brought to a standstill as the company struggles to find partners to collect medical data, he noted.

Japan as important partner

Relations between Korea and Japan have long been rocky because of Japan’s 20th century history of imperial atrocities against Korea and other Asian nations. Economically, however, the two countries need each other. According to Kim, how Vieworks grew as a global medical device maker exemplifies this. When Kim worked as an engineer for Samsung Aerospace Industries (now Samsung Techwin) in the early 1990s, the company set up a center in Tokyo to train its engineers, including Kim, as optics experts. “Some of Japan’s best optics experts imparted technical education to Samsung engineers for four years, on and off. In person and sometimes by fax, it was a tremendous learning experience for me and eventually it helped me grow as an optics researcher,” Kim said. After leaving Samsung, he joined Vieworks as its CEO in 2002. But the venture soon faced financial troubles as Medison, which was its main shareholder and customer, went bankrupt. “Fortunately, Toshiba offered us an important business deal in 2004,” he said. “Since then, we have provided the Japanese company with charge-coupled devices (CCD) cameras for its medical examination equipment, which it can sell at much higher prices.” A CCD is a light-sensitive integrated circuit that stores and displays data to create an image. Kim said what he learned from the partnership with Toshiba was its stringent product quality regulations. “Our products could not pass Toshiba’s inspection criteria initially. We learned much about its quality inspection system as we worked to meet the requirements,” he said. “Our partnership has been helpful financially and technically for both of us. From 2007 to 2008, the deal with Toshiba was critical as it accounted for 40 percent of our revenues and it still accounts for 7 to 8 percent of our revenues today.” According to the Institute for International Trade, a research institute under the Korea International Trade Association, Korea-Japan trade reached the peak of $108 billion in 2011 from $220 million in 1965. However, the partnership has been weak in recent years, thanks to various diplomatic and political disputes over historical issues. In 2014, trade volume between the two neighbors steadily shrunk to $86 billion.